We strive to achieve the best

The study and design of your cylinders

Thanks to the experience gained over 50 years of operation in Brescia, Stocchetta Cilindrici offers bespoke hydraulic cylinders that are efficient and effective according to the different industrial conditions in which they will be installed. The goal is to guarantee performance with reliable and long-lasting products.

The drawings are made in 3D and we provide the models on request. It is possible to include the 3 dimensions of the product in the drawing, in order to accurately assess overall dimensions.

Quick answers and quotes

Whether you need standard ISO or DIN cylinders, customised hydraulic cylinders, special bepoke cylinders or a consultation for a new project, we will provide you with quick answers and quotes.

The huge archive of cylinders we manufacture and the precise and accurate management of the final data of each order make us the absolute masters of the production cycle – necessary to create a product that suits your needs.

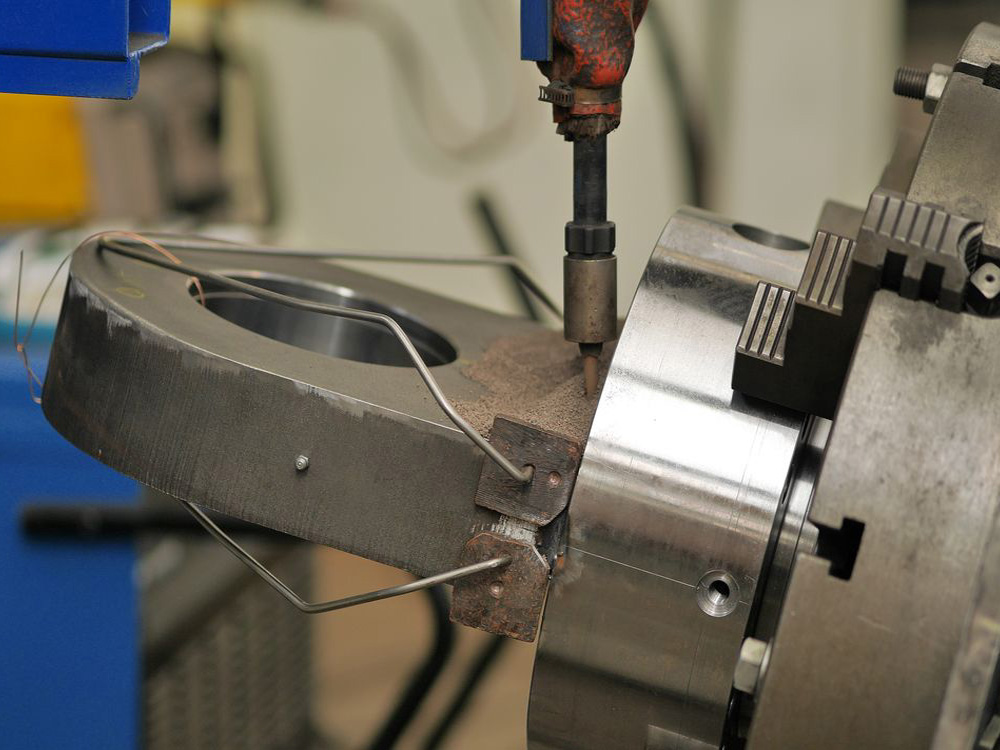

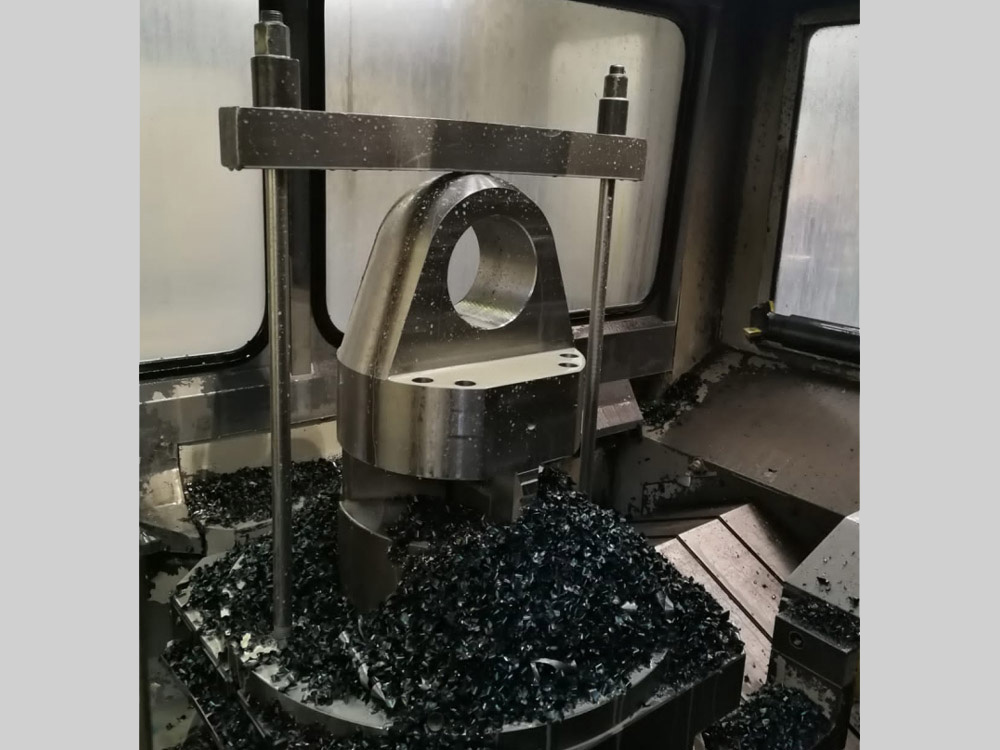

The art of bespoke production

Trust Stocchetta Cilindri, a leading company in the bespoke production of hydraulic and pneumatic cylinders: our know-how allows us to take advantage of an important competitive advantage, based on engineering and the optimisation of lean production, involving all business areas.

Compared to mass production, bespoke production is orientated towards development and personalisation in order to obtain tailor-made products in compliance with specifications.

Stocchetta 4.0

Production is monitored at every single stage and the progress is constantly monitored thanks to the application of Industry 4.0 which allows quick access to centralised information via the computer system. On the basis of the orders in progress, planning sets out the materials, components and processes necessary for the realisation of the finished products. Supply, governed by an advanced MRP system that constantly feeds the warehouses with standard materials, guarantees the delivery of finished and/or semi-finished components on schedule.

The use of new CNC numerical control machining centres allows us to carry out complex, high-precision machining and to optimise turnaround times. Our operators in charge of the final assembly and painting stages package a finished product of high manufacturing quality but we don’t stop there. We are careful to satisfy our customers also in terms of packaging and shipping. We implement customised procedures to deliver exactly what the customer wants.

Request information

We are your trusted hydralic and pneumatic cylinder partner, including after sale, thanks to our availability and speed of reply.Bespoke hydraulic cylinders